CASTECH's "Aspherical" Extraordinary Journey

Source:

Publish time:

2025-09-30

CASTECH's "Aspherical" Extraordinary Journey

In the article "To distinguish between “aspheric” and “spheric”, why to make it “perfect”?", we briefly introduced the definition, applications, and CASTECH's aspherical processing capabilities. To meet customers' "extraordinary" specification requirements, however, we must tread an "extraordinary" path. Today, we continue to delve deeper into CASTECH's "extraordinary" journey in precision CNC machining for aspherical lenses.

As mentioned in the previous article, aspherical lenses have long been favored by optical engineers for their ability to eliminate aberrations and enhance optical system performance. However, the high processing costs of high-precision aspherical lenses have made them daunting in both manufacturing and application fields. In recent years, with the rapid advancement of CNC and detection technologies, the fabrication processes for high-precision aspherical lenses have matured, and costs have gradually decreased. As a result, aspherical lenses are no longer "out of reach", replacing some spherical lenses in optical systems and enabling designers to create setups with fewer components, more compact structures, and superior performance.

Fabrication Processes for Aspherical Lenses

There are multiple technical routes for aspherical lens fabrication. Currently, the most mature and stable processes mainly include glass molding, Plastic molding, hybrid molding, single-point diamond turning (SPDT), and precision CNC machining. A comparison of the key advantages and disadvantages of these five processes is presented in Table 1.

Table 1: Comparison of Advantages and Disadvantages of Five Main Aspheric Manufacturing Processes

Serial No. | Aspheric Lens Manufacturing Process | Advantages | Disadvantages |

1 | Glass Molding Aspheric Lens | Suitable for mass production; lightweight, low cost | Low precision; low damage threshold; challenging precision mold fabrication; high mold cost; difficulty with medium to large apertures |

2 | Plastic Molding Aspheric Lens | Suitable for mass production; lightweight, low cost, high design freedom for complex shapes | Low precision; lowest damage threshold |

3 | Single Point Diamond Turning (SPDT) Aspheric Lens | Suitable for infrared crystals; fast delivery; high precision | High cost; surface tool marks; high surface roughness |

4 | Hybrid Molding Aspheric Lens | Suitable for multispectral applications; corrects both spherical and chromatic aberrations | Low precision; low damage threshold |

5 | Precision CNC Machined Aspheric Lens | Wide processing range; fast delivery; high precision; high damage threshold | High cost; low production capacity |

Among the five main aspheric machining methods, precision CNC machining offers the highest precision. Therefore, aspheric lens products for applications in laser and precision optics fields mostly adopt this method. Generally, the machining accuracy of aspheric surface shapes depends on the precision of the corresponding aspheric measurement methods. However, due to the high cost of non-contact interferometric measurement equipment, most aspheric lens manufacturers choose to equip lower-cost contact measurement instruments. Yet, the compromised measurement accuracy directly affects the machining accuracy of aspheric surface shapes. Thus, the guarantee of specifications for truly high-surface-precision aspheric lenses not only requires investment in precision CNC machining equipment but also demands the equipping of advanced non-contact interferometric measurement devices, and even the use of ion beam figuring (IBF) or magnetorheological finishing (MRF) for correction to achieve ultimate surface precision.

Castech’s Extraordinary Journey in Aspheric Optics

Castech, guided by its corporate mission of “Be a Powerful Booster of Optoelectronic Industry ”, is committed to providing customized high-precision optical component solutions to empower its customers.

Accordingly, for aspheric products, our ongoing research and development (R&D) focus is on advancing aspheric machining processes with higher precision and higher damage threshold.

First, in terms of process routes and testing infrastructure, Castech has established a comprehensive Aspheric Machining & Testing Center built on two core pillars:

Ultra-precision machining: Equipped with ultra-precision CNC machines from OptoTech (as illustrated in Figure 1);

Dual-mode testing: Equipped with Taylor Hobson’s tools:

Contact-type PGI profilometer;

Non-contact laser interferometric testing system LUPHO Scan (as illustrated in Figure 2).

By correlating real-time testing data with CNC machining parameters, we achieve quantitative fabrication of high-quality aspheric mirrors—ensuring every component meets strict precision requirements.

Figure 1 CNC machines from OptoTech

Figure 2. Non-contact laser interferometric testing system LUPHO Scantesting system LUPHO Scan

Manufacturing Example:

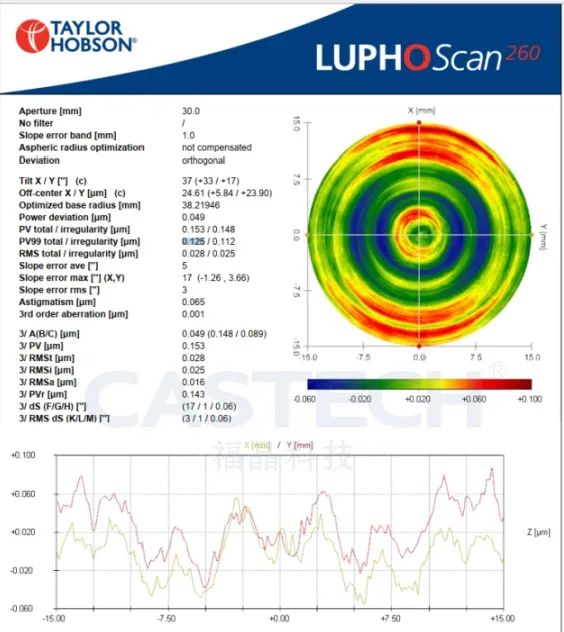

Using ultra-precision CNC equipment, we fabricated an aspheric lens with dimensions of Φ30×7mm. The achieved specifications include:

- Surface quality**: Better than 20/10 (scratch/dig)

- Surface irregularity (IRR)**: 0.112 μm (as shown in Figure 3)

All performance parameters met and exceeded the customer's customized requirements.

Figure 3. IRR Test Report of the Product Measured

by the Non-Contact Interferometer LUPHO Scan

When customers present extreme "extraordinary" requirements for aspheric product specifications, Castech's "exceptional" manufacturing capabilities come to the forefront.

After undergoing iterative CNC polishing and non-contact testing via the machining and testing center’s computer-controlled processes, the aspheric product achieves high-precision aspheric lenses or aspheric cylindrical lenses. For clients with ultra-stringent surface figure demands, the aspheric surface test data is imported into the Ion Beam Figuring (IBF) system. Using software simulation, the system precisely controls the ion beam’s dwell time in specific regions, enabling contactless, sub-nanometer surface correction to push the aspheric surface to its ultimate precision limit. The seamless integration of testing limits and machining limits—coupled with the "targeted correction on demand" processing philosophy—is fully demonstrated and implemented in practical manufacturing.

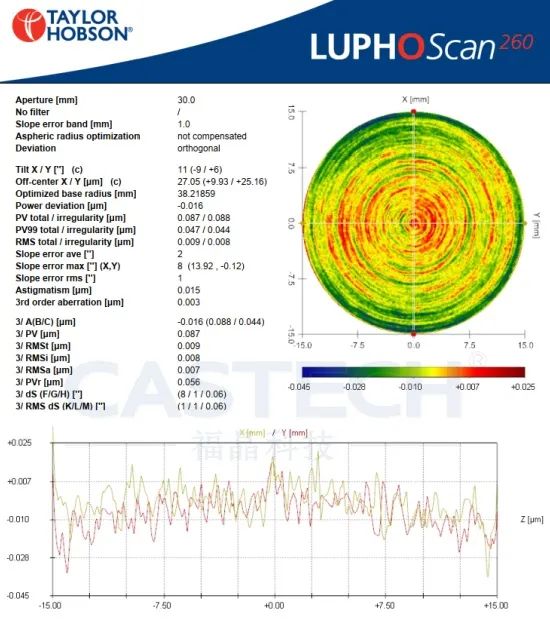

Manufacturing Example:

An aspheric lens measuring Φ30×7 mm was first machined using CNC equipment and subsequently underwent surface correction via Ion Beam Figuring (IBF). The final product achieved:

Surface quality: Better than 20/10 (scratch/dig)

Surface irregularity (IRR): 0.008 μm RMS (as shown in Figure 4.)

Figure 4. Testing Results of Ion Beam Figuring (IBF) Processing

Related Information