TSAG Crystal: A Magneto-Optical Material

Source:

Publish time:

2025-09-30

The Discovery of Magneto-Optical Crystals

Humanity's quest to unravel the interplay between light and magnetism spans centuries of rigorous exploration. This understanding originated from the phenomenon of natural optical rotation in crystals. In 1811, Dominique François Arago observed the rotation of polarized light as it passed through quartz crystals. A decade later, in 1821, Michael Faraday discovered the electromagnetic rotation effect (now known as the Faraday effect). These breakthroughs, followed by extensive experiments and practical applications, paved the way for magneto-optical materials in device fabrication, leading to the gradual identification and utilization of magneto-optical crystals.

Today, the dominant commercially available magneto-optical crystals are Terbium Gallium Garnet (TGG) and rare-earth-doped Bismuth Iron Garnet (RIG).

TGG crystals: Operational wavelength range of 400–1100 nm (excluding 470–500 nm).

RIG crystals: Operational wavelength range of 1000–5000 nm.

As optical isolators trend toward miniaturization and higher power densities, the demand intensifies for next-generation magneto-optical crystals featuring:

Higher Verdet constants (for stronger Faraday rotation and more compact designs),

Lower optical absorption (to minimize thermal lensing and heat-induced distortions).

The R&D and scalable production of such advanced crystals have thus become essential to push the boundaries of high-performance photonics.

Origin of TSAG Crystal

Terbium Aluminum Garnet crystal (abbreviated as TAG crystal) exhibits a large Verdet constant—20–30% higher than that of TGG—and lower absorption, approximately 30% less than TGG. However, TAG crystals are incongruent-melting and cannot be grown using the Czochralski method.

Scholars both domestically and internationally addressed this by substituting some Al³⁺ ions in the tetrahedral sites of the TAG crystal structure with Sc³⁺ ions, thereby achieving a balance in the ionic radii among cations. This innovation effectively promotes the formation of the TSAG single-crystal phase.

Extensive research demonstrates that TSAG crystals retain the same superior characteristics as TAG in terms of Verdet constant and absorption metrics.

CASTECH's Journey in Developing TSAG

CASTECH initiated the development of TSAG crystal growth processes in 2016, starting with 1-inch diameter sizes. Throughout the process, the team encountered numerous challenges, primarily including cracking and inclusions. Cracks frequently occurred during crystal growth, often rendering experiments impossible to continue.

The R&D team refused to give up. Through bold innovations—such as adjusting the formula, optimizing the temperature field, and modifying the growth atmosphere—they persevered. In the end, their dedication yielded results: the team successfully grew crack-free, inclusion-free TSAG crystal boules with a 2-inch diameter, a straight length exceeding 120 mm, and a weight of 1.2 kg.

Today, CASTECH can stably and in bulk supply large-size TSAG crystal components, as well as compact, high-power TSAG isolators.

Early-stage 1-inch TSAG crystal boule

Mature-stage 2-inch TSAG crystal boule

In 2020, CASTECH's TSAG magneto-optical crystal—renowned for its unique advantages and backed by mature, stable production processes—won the "OFweek 2020 Laser Industry Laser Components, Accessories & Modules Technology Innovation Award" at the OFweek Laser Industry Awards (Vico Cup).

Main Features of TSAG

Large Verdet Constant: 48Rad T-1m-1 at 1064nm, about 20% higher than that of TGG;

Low Absorption: <3000 ppm/cm at 1064 nm, about 30% less than that of TGG;

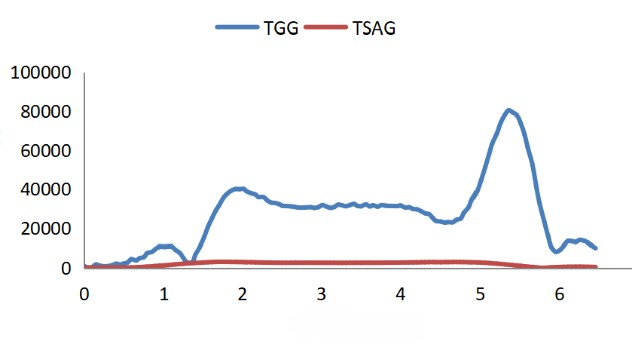

- At 532 nm wavelength: TSAG exhibits a bulk absorption of <3000 ppm/cm, while TGG exceeds 30,000 ppm/cm—an order of magnitude difference.

532 nm absorption curve

Product Specifications of TSAG Crystal

Maximum finished size | Dia.40x100mm |

Orientation | <15′ |

Wavefront distortion | <λ/8 @633 nm |

Extinction Ratio | >30 dB |

Bulk absorption | <3000 ppm/cm |

Diameter tolerance | +0.00 mm/-0.05 mm |

Length tolerance | +0.2 mm/-0.2 mm |

Chamfer | 0.1 mm@45° |

Flatness | <λ/10 @633 nm |

Parallelism | <20 arc sec |

Perpendicularity | <15 arc min |

Surface quality | 10/5 |

AR-coating | <0.2%@1064 nm |

Related Information